Origin: a Latin derivative

meaning "Gift of the Earth."

- Shop

-

Our Story

- View Our Story Home

- Who We Are. . . .

- What We Do. . . .

- Why We Do It. . . .

-

dōTERRA[doh-teh-ruh]

Pursue What’s Pure: The CPTG® Standard

Purity, Defined

When you buy an essential oil, it should be pure. Purity isn’t optional. It’s foundational. That’s why doTERRA prioritizes purity when selecting essential oils.

What Do We Mean by “Pure”?

A pure essential oil is unadulterated, which means three things:

- It’s sourced from nature rather than synthetically produced.

- It’s authentic, with a verified botanical identity through testing.

- It’s undiluted by fillers or additives—no added fragrances, dyes, preservatives, or undisclosed ingredients.

Simply put, a pure essential oil delivers a plant’s aromatic chemistry—uncompromised.

Why It Matters

The purity of an essential oil is its most important characteristic. Adulteration can affect safety and efficacy. Using an essential oil that isn’t pure not only wastes money, but it can also cause irritation or worse.

Many companies claim their oils are pure, but these claims are often unverified. For example, a recent study found two-thirds of lavender oils on the market are compromised.

Purity needs to be more than just a promise. It must be proven.

No Global Standard

Purity is a safety standard. However, despite increasing demands for pure products, there’s no internationally regulated definition of pure essential oils. Words like natural or therapeutic can be used freely, even when essential oils are stretched with synthetics or altered to cut costs.

Adulteration methods are constantly evolving, and it’s no longer enough to rely on tradition or trust alone.

The doTERRA Solution: CPTG Certified Pure Tested Grade®

doTERRA was founded on the basis of solving this problem. Customers needed a standard of testing that didn’t just detect the obvious but also uncovered the subtle.

CPTG testing is that safety and purity standard. It’s a multi-layered approach to purity and quality verification. That’s what makes doTERRA essential oils both effective and trustworthy.

Because the industry is constantly evolving, so is CPTG testing. It was built to outpace industry shortcuts.

Purity Begins Long before the Lab

At doTERRA, purity starts with people. Our sourcing model puts relationships first as we work with distillers and growers across more than 40 countries to support meaningful economic opportunities for those involved, protect native ecosystems, and build lasting partnerships. This focus and effort is known as Co-Impact Sourcing®, and it’s at the center of everything we do.

Through Co-Impact Sourcing, we demonstrate our commitment to responsibly sourcing essential oils and other gifts of the earth with care and respect for people and planet. Our standards are centered on:

- High quality botanical sourcing

- Transparency and trust in business transactions

- Fair labor practices and safe working conditions

- Sustainable and regenerative agriculture that protects and renews natural resources

Achieving True Purity through the CPTG Standard

Not all essential oils are created equal. You can tell if yours meets the highest standard through:

- Plant sourcing

- Production integrity

- Comprehensive testing

- Packaging and storage

These four pillars comprise doTERRA CPTG testing.

Plant Sourcing: It Starts with the Field

Our partnerships allow us to grow in regions with optimal conditions for producing quality plants. We’ve found the highest-quality essential oils come from plants grown in ideal environments, harvested at peak potency, and cared for by people who are treated with dignity.

We aim to ensure every plant is:

- The best species—chosen for its concentration of key compounds

- Grown with care for the planet and in its ideal environment where soil, climate, and altitude optimize potency

- Harvested at the exact moment when its chemistry peaks

- Managed using sustainable, responsible practices

To achieve these aims, we partner with artisans from countries who have refined their practices through an integrated approach to agriculture, producers, and extraction. Many of our partner producers have been honing their craft for generations, bringing unparalleled expertise to every step of the process—planting to distillation.

doTERRA is actively shaping the future of plant sourcing and extraction across the food and beverage and health and fitness industries. Our commitment to purity and sustainability is setting a new global standard—one that others are now striving to meet.

As others around the world elevate their practices to keep pace, the ripple effect is raising the bar for quality industry-wide!

Production Integrity Means No Shortcuts

Once plants have reached maturity and are harvested, they’re then extracted. We partner with expert distillers, artisans, engineers, and scientists from all over the world to apply careful, proven techniques to extract these delicate essential oils, absolutes, and extracts. This measure ensures the most potent and beneficial chemical profile on a consistent basis—tested and dependable.

Comprehensive Testing: Multiple Layers of Protection

When an extracted essential oil arrives at a facility, rigorous testing begins to ensure it meets our quality standards through a series of both internal and third-party tests.

First, our quality assurance process involves multiple rounds of testing throughout the finished-good production cycle, including checks at the beginning, middle, and end of each run.

Then to ensure objectivity and transparency, we partner with independent laboratories that specialize in essential oil analysis.

We don’t just rely on one test—we run many. Each aromatic essential oil requires different types of testing methods, depending on its chemistry and biodiversity, extraction method, and other factors. Each test adds a new layer of verification and catches what others miss in a thorough pursuit to ensure every drop is pure, potent, and effective.

Gas Chromatography/Mass Spectrometry (GC/MS)

GC/MS separates and identifies the natural chemical compounds in an essential oil, showing us exactly what’s in it and in what amounts. This test helps confirm both the identity and purity of an essential oil, ensuring it matches nature’s blueprint.

Liquid Chromatography/Mass Spectrometry (LC/MS)

LC/MS detects compounds that GC/MS might miss, especially nonvolatile substances like:

- Pesticides

- Carrier oil adulterants

- Photosensitizing compounds (like furanocoumarins)

This test helps confirm both the safety and authenticity of an essential oil.

Fourier-Transform Infrared Spectroscopy (FTIR)

FTIR uses light to determine an essential oil’s “chemical fingerprint.” This test helps verify the structure of an essential oil matches the high-quality standard expected from the plant. We want to ensure it’s structurally sound and authentic—exactly what Mother Nature gave us.

Organoleptic Testing

As innovative as machines are, they can’t replace human senses. Experts use sight and smell to identify instant red flags in an essential oil, such as unusual appearance, aroma, or color.

Microbial Testing

Microbial testing screens for harmful bacteria, mold, and other microorganisms to ensure an essential oil is clean and safe for use.

Heavy Metal Testing

ICP-MS (inductively coupled plasma mass spectrometry) is used to detect even trace amounts of heavy metals like lead, mercury, or arsenic. The sample is then run through a mass spectroscope, which separates the sample into its elemental parts and provides a reading about which elements are present and at what quantities.

Chirality Testing

Chirality testing checks the 3D shape of molecules. Similar to how your right hand and left hand look similar but aren’t identical, in nature molecules have a preferred handedness and are directional. Lab-made versions don’t mirror like that. Chirality helps reveal hidden synthetics.

Optical Rotation

Optical rotation shines light through an essential oil to see how it bends. If the angle isn’t what we expected, then the essential oil is compromised.

Specific Gravity

Specific gravity is a measurement of how dense an essential oil is compared to water. Pure essential oils have specific known ranges. If an oil falls outside that range, then it could be diluted.

Refractive Index

Refractive indexing shows how light slows down through an essential oil. It’s another indicator of authenticity and consistency.

Peroxide Value

Peroxide value is a test for oxidation and freshness. A high peroxide value means an essential oil may have started to break down or spoil, which reduces both effectiveness and safety.

Isotopic Analysis

Every plant carries a signature based on the carbon isotope ratios in its environment. If an essential oil was synthesized or tampered with, these natural ratios change, and isotopic analysis catches it. Even the source of the plant (like the country it comes from) affects this ratio, so this test can catch hidden adulteration.

Chemometric Ratio Analysis

Chemometric ratio analysis identifies the ratio of different compounds in an essential oil and compares them to nature’s original creation. If the numbers don’t match, then something is off.

Lab Distillation Authentication

We distill plant materials in a lab and compare the chemistry to what we received from the grower. If they match, then it confirms an essential oil was properly and honestly distilled.

Targeted Synthetic Marker Detection

Targeted synthetic marker detection searches for specific synthetic compounds that should never be in pure essential oils, such as trans-furanolinalool oxide acetate in Lavender oil. This test can catch even sophisticated fakes.

High-Performance Thin-Layer Chromatography (HPTLC)

HPTLC spreads an essential oil across a special plate and creates a visual “fingerprint” of its compounds. This test makes it easy to spot adulteration or contamination by comparing it to a known pure sample.

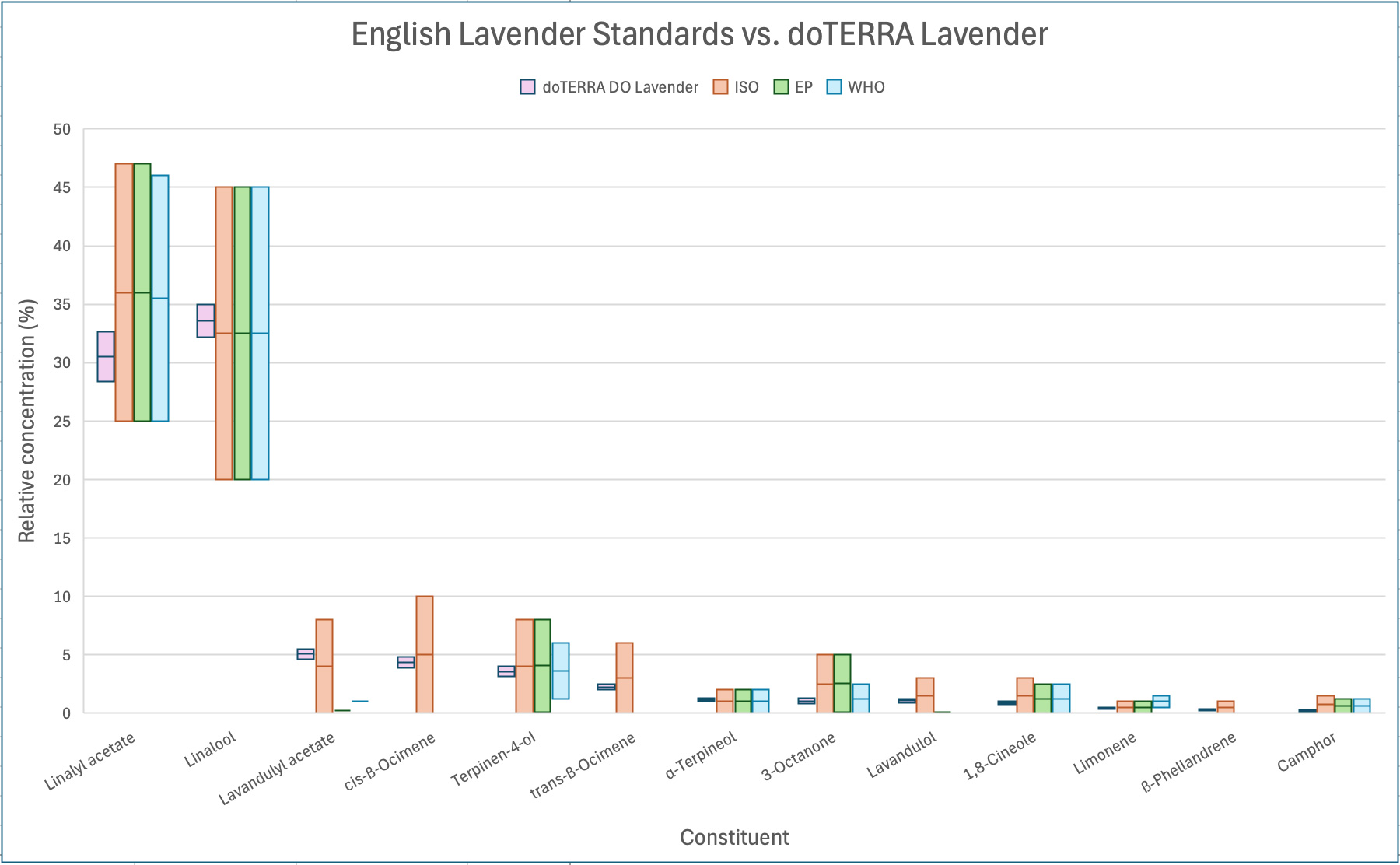

This graph shows constituents present in our final testing of Lavender essential oil and compares them to the expected global standard. As you can see, doTERRA Lavender meets those global standards with great consistency, ensuring you get pure chemical constituents in every drop.

Packaging and Storage

Once an essential oil batch has been through each stage of testing, it’s bottled in UV-protective glass and stored to protect from heat and light. This step preserves its natural potency for a longer time.

Purity Is a Pursuit

doTERRA doesn’t claim to be perfect—we claim to be relentless. Adulteration methods evolve, and we continue expanding and refining our processes of rooting out even the slightest traces of adulteration. Each test is another layer of security, eliminating doubt.

Our goal isn’t just to confirm purity. It’s to earn your trust through transparency, consistency, and continuous innovation.

Purity is an ongoing pursuit. That’s why we test more than anyone else in the industry. Our uncompromising standards have enabled research that’s reshaping how the world views essential oils. doTERRA products are studied and used in hospitals, labs, and clinics across the globe because of this standard.

See for Yourself

While most companies keep their processes behind closed doors, we invite you to take a closer look. Because when you know the story, you understand the standard.

To discover how your essential oil was CPTG tested, visit sourcetoyou.com to:

- Trace your essential oil back to its country of origin.

- View GC/MS test results for your specific batch.

- Learn about the growers and communities behind the bottle.

Choose Pure—Choose doTERRA

We believe quality has to be proven, not just claimed.

When you choose doTERRA, you’re not just choosing a brand or an essential oil. You’re choosing a philosophy and a promise that values purity—not just in testing, but also in intention. You’re joining a health revolution that leads with science, partners with nature, and puts people first.